JC Machine Works – Current Bridge Projects

Point-No-No Point Swing Bridge

Consolidated Rail-Road – Manufacture components for 2 center wedge assemblies inclusive of all field removal of existing equipment, shop machining of new and rehabilitated components and field installation of equipment.

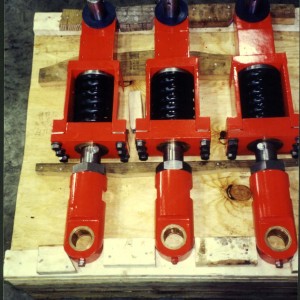

LaRose Vertical Lift Bridge

Louisiana D.O.T – Manufacture operating machinery components including 8 rollers bearing for main pinions, 4 floating shafts with couplings, support weldments for new machinery, supplemental counterweight rope components, 4 new air buffer cylinders, and 2 complete traffic barrier mechanisms.

Delair Vertical Lift Bridge

Norfolk Southern Rail-Road – Manufacture a total of 96 take-up components including adjustment nuts with thrust washers.

JC Machine Works – Completed Bridge Projects

Paulsboro Lift Bridge

Consolidated Rail-Road – Machine 4 counterweight sheaves including full NDT testing and install the shafts onto the sheaves.

Completion Date: August 2015

Townsends Inlet Drawbridge

Cape May County, Public Works – Manufacture new gear racks with integral web/flange, new drive pinions, new open gear reduction stages including shafts, new bronze bearings or all shafts, alignment shim sets and hardware. Also, manufacture new complete span lock system to include lock bars, guides with bronze shoes, crank shaft, reducer/motor and support weldment; assemble all and shop test.

Completion Date: July 2015

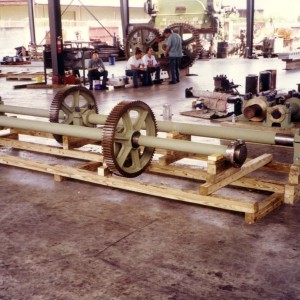

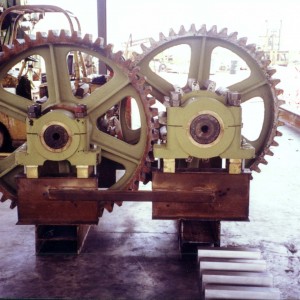

Atlantic Beach

Nassau County Bridge Authority, NY – Rehabilitate 4 existing secondary gear frames to include a total of 8 new large diameter bull gears with new shafts, a total of 8 drive pinions press fitted onto shafts, 8 new gear guards, new floating shafts with couplings, hardware and motor mounting plates. Also, new bronze shoes/guides along with hardware, shim sets actuator covers, support weldments and link arms for the span lock mechanism.

Completion Date: December 2014

Santay Pedestrian Bridges (2)

Ecuador – Manufacture 8 sets of trunnion shafts, trunnion hubs with backing rings, hardware and pillow block bearing assemblies; assemble the trunnion hubs onto the trunnion shafts. Also, manufacture 4 sets all new open gears, pinions, gear racks, pillow block bearing assemblies, shafts for the operating machinery.

Completion date: April 2014

Ouachita River Bridge

Louisiana D.O.T – Manufacture 4 sets of counterweight trunion machinery to include fabricated housings, bearings, sleeves, pins/shafts, hanger plates and associated hardware. Field install all the new machinery; remove the existing machinery and install new on all 4 leaves.

Completion date: September 2013

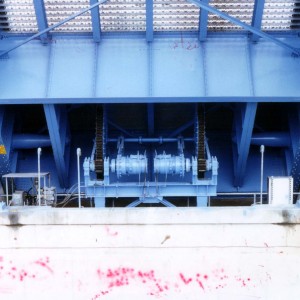

Snohomish Vertical Lift Bridge

Washington D.O.T. – Manufacture/supply 4 sets of sheave machinery to include, sheaves, ring gears, shafts, bronze bushings and bearing housings with associated hardware.

Completion date: May 2013

4th/7th Avenue Bascule Bridge

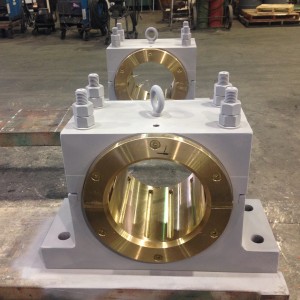

City of Fort Lauderdale D.O.T – Manufacture one new pinion shaft and two new bronze bearing shells and supply two coupling sets. Field remove existing components and install new pinion shaft and bearing shells.

Completion date: February 2013

Gilmerton Road Bridge

Virginia D.O.T. – Manufacture 2 sets of fixed bearing assemblies and 2 sets of expansion bearing assemblies along with all machined mounting hardware and shim sets.

Completion Date: January 2013

Blynman Bridge,

Massachusets D.O.T – Manufacture a total of 12 pillow block bearings, 4 pinions with pinion shaft, couplings, 4 gear racks with mounting hardware and shim sets and reducer support weldments. All the machinery, including new electric motors, where shop assembled and aligned and delivered as drop-in units.

Completion date: July 2012

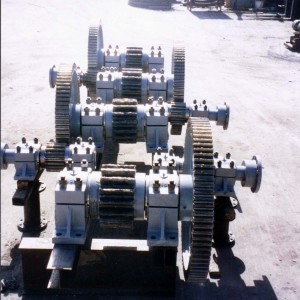

Swing Bridge No 220.62 over Lake Charles

Union Pacific Rail-Road – Manufacture 12 new replacement integral gear rack & rolling track welded segments. Also, manufacture the two mating drive pinions along with the drive shafts, upper open gear set (large bull gear + pinion), pillow block bearing assemblies, gear reducers and motors.

Completion Date: October 2011

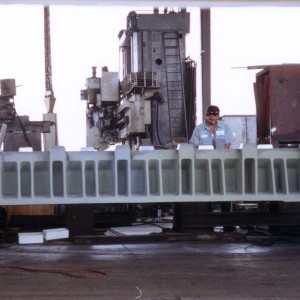

Roosevelt Island Bridge,

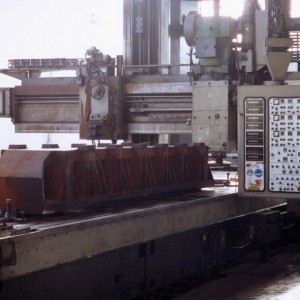

New York City, D.O.T – Manufacture all new bridge lifting machinery and equipment. The top cap of the towers, or grillage beam assembly, was erected and aligned on the shop floor; all the operating machinery components we assembled and aligned onto the grillage beam assembly (replicating the field machinery package) and shipped as single drop-in units.

Completion date: August 2011

Pekins Lift Bridge No 88.96

Union Pacific Rail-Road – Manufacture 4 new sets of complete counterweight rope sheaves to include the fabrication & machining of the sheaves, the manufacturing of the sheave shaft and 8 sets of bronze pillow block bearings.

Completion Date: September 2010

Bridge No. 7 over Elizabeth River

Norfolk Southern Rail-Road – Manufacture 2 new sets of flat track plates and curved tread plates to replace the existing in-kind. Also manufactured new rolled segmental angles with the exact bolt-hole locations as the existing trunnion girder where they were mounted onto.

Completion date: May 2009

Spuyten Duyvil Bearing Replacement

AMTRAK – Manufacture replacement pillow block bearing assemblies – both from traditional bronze material and from new Thordon self lubricating bushing material to match field conditions.

Completion Date: November 2008

Bridge of Lions

Florida D.O.T. – Manufacture 4 complete sets of track and tread rolling plates, 4 complete sets of articulating tail lock mechanisms, 2 complete sets of span lock mechanisms and 2 complete operating machinery systems with flat gear racks, struts, pinion shafts and support pedestals. Field Installed Machinery.

Completion date: July 2008

7th Street Bridge

Michigan D.O.T. – Manufacture new gear rack frame with internal gear rack segment along with new pinions, machinery shafts and machinery supports. Three right angle gear reducers are being coupled together via floating shafts, couplings and roller bearings to transmit all of the operating torque. All the machinery will be installed, aligned and tested in the shop prior to shipping.

Completion Date: January 2008

Johns Pass

Florida D.O.T. – Manufactured 8 complete sets of trunnion machinery including 8 trunnion shafts, 16 hubs (double webbed), backing rings and 16 trunnion bearings. The operating machinery includes 8 segmental integral gear racks-rack frames, 8 pinions shafts and structural steel supports – all these will be shop installed and aligned prior to leaving for the jobsite.

Completion date: December 2007

Hamilton Avenue Bridge

City of New York D.O.T. – Installed/assembled the trunnion shafts, trunnion hubs and main girders together. Also, assemble, align, permanently fasten and test the complete operating machinery for 2 bascule leaves, to include: open gearing, gear reducers, main motors, brakes, auxiliary motors, auxiliary hydraulic system and three complete span lock mechanisms.

Completion Date: March 2007

PGA Blvd.

Florida D.O.T. – Manufactured 4 complete sets of trunnion machinery including 4 trunnion shafts, 4 hubs, backing rings, 8 trunnion bearings, instrumentation equipment components and lexan covers. Also manufactured 2 complete sets of operating machinery including 4 segmental gear racks, 4 pinions shafts, floating shafts, structural steel supports – all these items were shop installed and aligned prior to leaving for the jobsite.

Completion date: January 2007

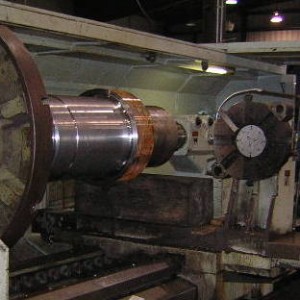

Pamunkey River Bridge

Virginia D.O.T. – Manufactured 4 trunnion machinery sets including 4 trunnion shafts – 32” in diameter x 201” long, 4 hubs, backing rings and 8 trunnion bearings with a 40” journal face. The operating machinery including 4 integral rack-rack frame gear racks with a 8-1/4” CP x 23” face, 4 pinions shafts with a 50” pitch diameter, structural steel supports and 2 complete span lock units – all these items were shop installed and aligned prior to leaving for the jobsite.

Completion date: November 2006

Martin Luther King Bridge

City of Toledo D.O.T. – Manufactured 8 complete sets of track and tread rolling plates with a 36” face width and 6” thick cross section. The machinery included 8 sets of linear gear racks with a 7” CP and a 18” face width, 8 rack pinion shafts 19” in diameter x 150” long and a complete machinery pedestal (10’ wide x 19’-6” long) where all of the reducers, motors, brakes, clutches and emergency operating system completely set in.

Completion date: July 2006

Wantagh State Parkway

New York D.O.T. – Manufactured 8 complete sets of trunnion machinery including 8 trunnion shafts, 8 hubs, backing rings, 16 trunnion bearings and 16 lexan covers. Also manufactured 4 complete sets of operating machinery including 8 segmental gear racks, 8 pinions shafts, floating shafts, structural steel supports – all these items were shop installed and aligned prior to leaving for the jobsite. Lastly, manufactured 4 complete sets of span locks consisting of 4 lockbars, front and receiver guide castings and bronze shoes – all items shop installed and adjusted for fit verificatation. Field Installed Machinery to include reducers, shafts, gear racks, etc.

Completion date: March 2005

Little River and Socastee Swing Bridges

South Carolina D.O.T. – Contract consists of the rehabilitation of 2 identical swing bridges. The work shall include the manufacturing of 2 segmental gear racks and pinions, 2 complete center pivot bearing assemblies and a total of 6 wedge drive assemblies. The wedge drive assemblies include the machining of floating shafts with couplings, single and double activated cam arms, connecting arms and gear reducers.

Completion date: October 2004

Canadian Pacific Railway – Bridge 282.21

Canadian Pacific – Manufacture new gear racks and pinions along with two open gear sets, pillow block bearings, flanged bearing housings with bronze bushings, machinery shafts and machinery supports. Supply main gear reducer mounted onto a common support and align – all the machinery was completely assembled and tested prior to shipment.

Completion date: August 2004

Stutson Street Rolling Lift Bridge

New York D.O.T. – Structurally machined 4 new sets of Track and Segmental Curved Tread plates for the rolling lift bridge and performed a roll thru test. Engineered and coordinated the integration of all the mechanical components. Machinery includes the manufacturing of 4 gear racks and pinions, 4 machinery output shafts and machining of 4 custom designed roller bearing housings. All parts will be shop assembled, fitted and aligned prior to shipment.

Completion date: April 2004

Dania Beach Blvd. Bascule Bridge

Florida D.O.T. – Fabricate sidewalk/span lock brackets. The brackets will be fabricated, stress relieved and machined to fit new circular flange type span lock guides and receivers. All components will be assembled and install in the shop.

Completion date: September 2003

Fulton Avenue Bascule Bridge

Westchester County, NY – Manufactured 3 complete sets of gear driven span lock units. This included the machining of guides and receivers, bronze wear plates, lock bars, connecting arms, cams and pins – all connected to a linear gear motor drive system. All units were installed, adjusted and tested prior to shipping.

Completion date: June 2002

BlackWater Swing Bridge

CSX Transportation – Manufactured new double spherical “fish eye” type elliptical bronze bearing bushing for the center pivot of the swing bridge along the outer bearing housing.

Completion date: May 2002

Glen Island Bascule Bridge

Westchester County, NY – Manufacture new internal gear rack segment along with new pinions, machinery shafts and machinery supports. Three gear reducers were involved in the project which were coupled together via floating shafts, couplings and roller bearings. All the machinery was installed, aligned and tested in the shop prior to shipping.

Completion date: February 2002

10th Street Rolling Lift Bridge

Michigan D.O.T. – Manufactured new pinion shaft, pinion, spherical flanged collar bearing and split spherical bronze bearing bushing for a rolling lift bridge. Assembled all the components together and tested prior to shipping.

Completion date: December 2001

N.W. 79 Street Bascule Bridge, East Bridge

Florida D.O.T. – Supply new gear reducer and machinery base. Field remove the existing reducer and replace with a new reducer and base. Field align all motor and brakes and floating shafts.

Completion date: December 2001

N.W. 5th Street Bascule Bridge

Florida D.O.T. – Acted as general contractor to repair all areas of the movable bridge (structure, machinery and masonry) that was damaged by a barge. The repairs consisted of major structural restoration of the main girder flanges and heat straightening of main girders itself, as well as hand rail repairs, sidewalk bracket repair and traffic gate support structures. Mechanical repairs consisted of verifying the trueness of the trunnion shafts and replacing trunnion bronze bearing bushings. All the work performed was done on an emergency basis with the bridge tied in the open position.

Completion date: October 2001

Knox Road (HighBridge) Bascule Bridge

Florida D.O.T. – Machined 4 trunnion shafts in the field to a specified bearing tolerance, then installed roller bearings and housings along with support masonry plates. Also, machined and installed new bronze bushing bearings on all the existing pillow block bearing housings.

Completion date: October 2001

S.R. 84 Bascule Bridge

Florida D.O.T. – Fabricated and machined 1 new Hopkins Frame. Removed all the existing machinery from the damaged Hopkins Frame and transferred it over to the new frame. Installed, aligned and tested the new Hopkins Frame. Also, machined 4 trunnion shafts in the field and manufactured new bronze bearing bushings to fit the new shaft diameter and existing bearing housings.

Completion date: September 2001

South Fork New River Rolling Lift Bridge

CSX Transportation – Manufactured new racks and pinions, pillow block bearing housings with the bronze bearing bushings, flanged bearing housings with the bronze bearing bushings, machinery shafts, sprockets and machinery supports. All the machinery was completely assembled and tested prior to shipment.

Completion date: August 2001

Cowan Lorraine Rolling Lift Bridge

Mississippi D.O.T. – Structurally – manufactured 8 new sets of Track and Segmental Curved Tread plates for the rolling lift bridge and performed a roll thru test. Engineered and coordinated the integration of all the mechanical and hydraulic system on the bridge. Mechanically – manufactured all new open gears, pinions and racks (over 20 bull gears, 28 pinions and 8 gear racks), manufactured 32 machinery shafts and machined 8 flanged bearing housings. Shop assembled and fitted all the gears, pinions, bearings onto the shafts prior to shipment.

Completion date: June 2001

Shaws Cove Swing Bridge

Amtrak – Fabricate and machine 8 sets of spring activated Mitre Lift brackets for the ends of the bridge rails; this includes the manufacturing of new shafts, couplings, support pedestals, gear reducers and drives. All items were assembled, aligned and tested prior to shipping.

Completion date: May 2001

Spuyten and Duyvil Swing Bridge

Amtrak – Manufacture new pinion shafts for the swing bridge and machine new custom designed bearing housings. Assemble and fit roller bearings and couplings onto shaft for shipment.

Completion date: April 2001

N.W. 79th Street Bascule Bridge, West Bridge

Florida D.O.T. – Remove the existing 8 damaged hydraulic cylinders operating the bridge and replace with new cylinders. Make all the hydraulic connections and test the bridge before turning over to the owner.

Completion date: March 2000

S.W. 4th Avenue Bascule Bridge

Broward County, FL – Similar scope of work as the S.W. 3rd Avenue Bascule Bridge. Dis-assembled machinery components from the bridge (gears, shafts and pinions), removed them and rehabilitated all items in the shop. Machined and installed new bronze bushings onto existing housings, re-assembled all the machinery in the field and operated/tested the bridge before turning over to the owner.

Completion date: February 2000

Commercial Blvd. Bascule Bridge

Florida D.O.T. – Manufactured 4 new gear rack segments. Also, machined 4 trunnion shafts in the field and manufactured new bronze bearing bushings to fit the new shaft diameter and existing bearing housings.

Completion date: October 1999

S.W. 3rd Avenue Bascule Bridge

Broward County, FL – Dis-assembled machinery components from the bridge (gears, shafts and pinions), removed them and rehabilitated all items in the shop. Machined and installed new bronze bushings onto existing housings, re- assembled all the machinery in the field and operated/tested the bridge before turning over to the owner.

Completion date: September 1999

Hillsboro Blvd. Bascule Bridge

Florida D.O.T. – Machined 4 trunnion shafts in the field and manufactured new bronze bearing bushings to fit the new shaft diameter and existing bearing housings.

Completion date: July 1999

Roosevelt Blvd. Bascule Bridge

Florida D.O.T. – Engineered and coordinated the integration of all the machinery elements, to include the fabrication of 4 new outboard machinery pedestals, 8 new pillow block bearings with new bronze bushings, 4 new pinion shafts and 4 new rack segments. Assembled, aligned and tested all the components prior to shipping. Supplied new primary gear reducers with floating shafts and couplings. Also, machined 4 trunnion shafts in the field and manufactured new bronze bearing bushings to fit the new shaft diameter and existing bearing housing.

Completion date: December 1998

Cermak Road Rolling Lift Bridge

City of Chicago, IL – Manufactured 4 new gear rack segments and 8 sets of open gears/pinions. Machined new bronze bearing bushings and installed them onto all 32 existing bearing housings. Rehabilitated 4 output machinery shafts, machined 8 new machinery shafts and bearing housings, then assembled all the new gears, pinions and bearings.

Completion date: July 1998

Andrews Avenue Bascule Bridge

Broward County, FL – Field machined 2 trunnion shafts in place and machined new bronze bearing bushings to fit the new shaft diameter and the existing housing.

Completion date: June 1998

Knapps Narrows Rolling Lift Bridge

Maryland D.O.T. – Engineered and coordinated the integration of all the mechanical and structural elements for the bridge. Structurally – manufactured 2 new sets of Track and Tread plates for the rolling lift bridge and performed a roll thru in the shop prior to shipping. Mechanically – manufactured all new machinery components to include: new gear racks, pinions, pinion shafts, bearings and machinery pedestals. Shop assembled, aligned and tested all the machinery prior to shipment.

Completion date: May 1998

Trail Creek Swing Bridge

Amtrak – Manufacture 2 sets of the wedge drive machinery system. The machinery consisted of new gear drive motors with double activated cam lever arms, with floating shafts, and connecting arms that coupled onto a series of jacking plates.

Completion date: February 1998

Miami Airport Extension Rolling Lift Bridge

Tri-Rail Authority, FL – Manufactured new machinery pedestals for the motors, brakes, bearings and open gearing; installed and aligned all the components for proper fit in the shop.

Completion date: January 1998

Sunny Isle’s Bascule Bridge

Florida D.O.T. – Designed a new bearing housing configuration to fit on the inside of 2 existing gear reducers to minimize the deflection caused by the pinion and gear sets. Installed the new housing onto the gear reducer in the field and bored the housing in-line for the proper gear/pinion center distances. Re-assembled the gear reducer, adjusted it and tested in the field.

Completion date: January 1998

Hillsboro Inlet Bascule Bridge

Florida D.O.T. – Fabricated 2 new outboard machinery pedestals, 4 new pillow block bearings with new bronze bushings and 2 new pinion shafts then shop assembled and aligned all the components. Supplied new primary and secondary gear reducers with floating shafts and couplings, then, coordinated the integration of all the machinery elements. Also, machined the trunnion shafts in the field and manufactured new bronze bearing bushings to fit the new shaft diameter and existing bearing housing.

Completion date: November 1997

Royal Park Bascule Bridge

Florida D.O.T. – Fabricated 4 sets of new span lock receivers, guides and sockets along with new lock bars, then adjusted them with new bronze shoe wear plates.

Completion date: August 1997

Portal Swing Bridge

Amtrak – Fabricated, machined, assembled and tested 8 sets of spring activated Mitre Lift brackets for the ends of the swing bridge rails.

Completion date: July 1997

Spanish River Bascule Bridge

Florida D.O.T. – Field machined/bored 2 the existing Hopkins Frame and clevis bases in-line to remove the existing wear. Machined new clevis pins for the oversized machine bore along with new bronze bearings bushings. Also, fabricated new span lock receivers, guides and sockets and adjusted them with new bronze shoe wear plates.

Completion date: December 1996

Lake Worth Bascule Bridge

Florida D.O.T. – Fabricated 4 new outboard machinery pedestals for the secondary open gear drive system along with new turned bolts and bronze bearing bushings for the pillow block bearings. Also, fabricated new span lock receivers, guides and sockets and adjusted them with new bronze shoe wear plates.

Completion date: September 1996

Indian Rocks Bascule Bridge

Florida D.O.T. – Fabricated 2 new Hopkins Frames for hydraulic motors, then installed and aligned new pillow block bearings, pinions shafts, torque arms and link arms (all mfg. by JCMS) onto the frame in the shop. Also manufactured 4 new mating segmental gear racks. (Identical machinery layout and scope of work as the Cortez Bascule Bridge).

Completion date: December 1995

Linton Blvd. Bascule Bridge

Palm Beach County, FL – Fabricated 4 new outboard machinery pedestals for the open gear drive system, then shop aligned and installed all the open gear sets and pillow block bearings onto pedestals with turned bolts. Also, manufactured 4 new trunnion bronze bearing bushings from existing field taken dimensions to fit onto housing and shaft.

Completion date: November 1995

Cortez Bascule Bridge

Florida D.O.T. – Fabricated 2 new Hopkins Frames for hydraulic motors, then installed and aligned new pillow block bearings, pinions shafts, torque arms and link arms (all mfg. by JCMS) onto the frame in the shop. Also manufactured 4 new mating segmental gear racks.

Completion date: October 1995

Main Street Bascule Bridge

Florida D.O.T. – Manufactured 4 new sets of bull gears and pinions for the open gear drive system and press fitted them onto the existing shafts. Also machined new bronze bearing bushings and installed them onto the existing pillow block housings.

Completion date: August 1995

Tamiami Swing Bridge

Dade County Public Works, FL – Manufactured the center gear rack along with the pinion shaft in 6 segmental sections.

Completion date: February 1995

N.W. 12th Avenue Bascule Bridge

Florida D.O.T. – Manufactured 3 sets of the high speed input gears and pinions for both leaves along with new shafts and new bronze bearing bushings for all of the existing pillow block bearings. Performed the installation all of the pinions, gears and bearings in the field with our field crew of mechanics.

Completion date: June 1994

Moveable Bridges

Moveable Bridges